Europe's Largest Repair Center for Driven/Live Tooling & Angle Heads

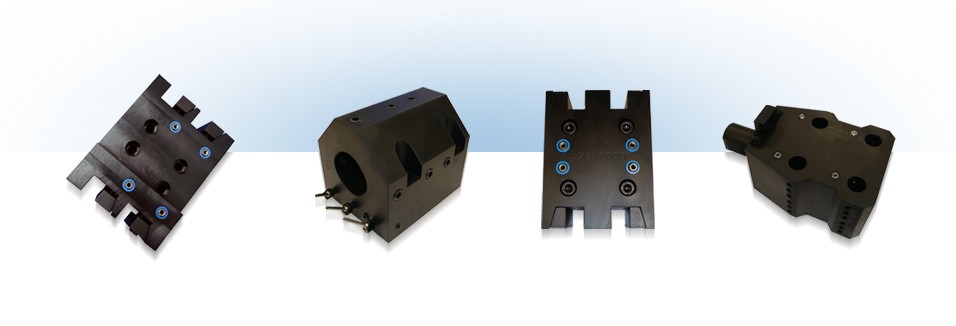

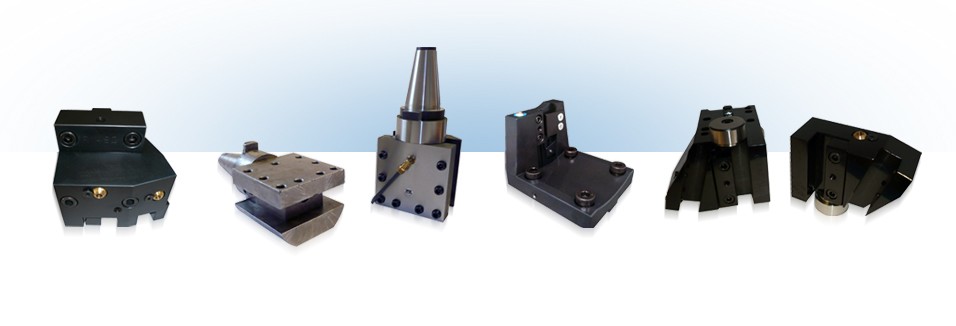

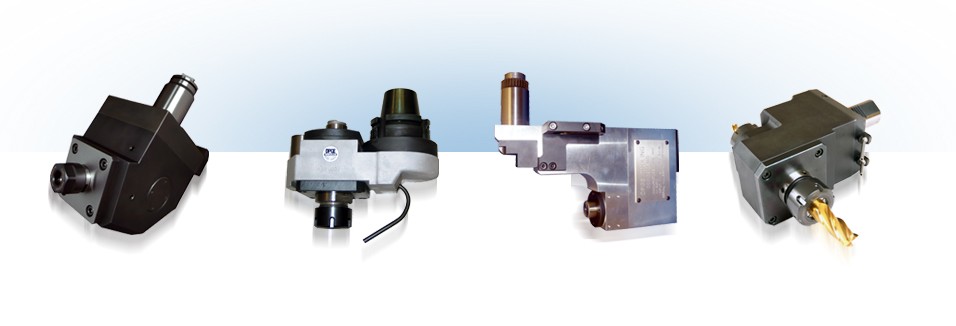

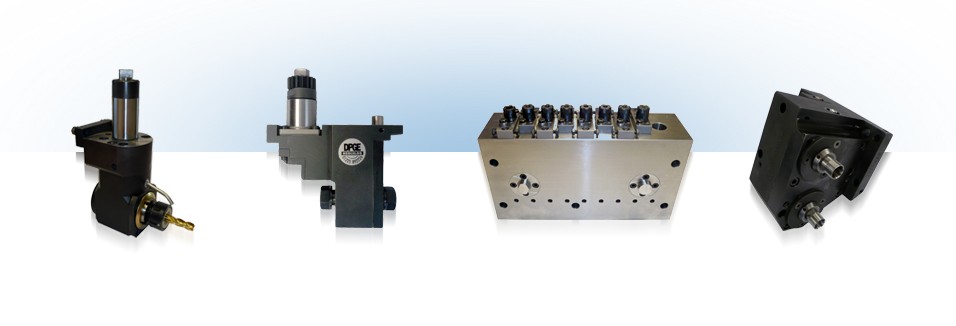

We repair & service all makes and models of Driven, Static Tooling and Angle Heads.

Do you have any Tooling that;

- Has seized,

- Creates a poor surface finish,

- Is drilling off centreline,

- Overheating,

- Noisy,

- Damaged due to an impact,

- Or has general wear & tear.

Send these Tools to us and let us return them to the original condition, operating to the manufacturers specifications

Most Tools are serviced within 5-7 working days and for 1/3rd of the price of a New Tool

48 Hour Turnaround is also available dependant on Tool damage

Our unique services are used nationally & internationally and our comprehensive tool service includes the following;

Tools disassembled;

All components are checked for wear, damage & cracks

All parts are chemically cleaned

Quotation formulated & sent to customer

Tools assembled;

Tools are rebuilt using KLUEBER ISOFLEX NBU15 GREASE and various Loctite Products & Top Quality precision bearings & seals

Replacement parts manufactured in house or purchased from the OEMs

Collet taper reground if necessary

Tool checked for alignment & corrected if required

Every tool is individually marked for traceability

Preventative Maintenance Schedule created in Microsoft Excel format and a copy is sent to you with periodic health checks emailed.

We service all makes including the following manufacturers Tooling;

Alberti, Algra, Alps, Benz, Bristol Tool, Eroglu, Evermore, EWS, Gerrardi, Eppinger, Heimatec, Holdwell, Madaula, Mario Pinto, MT Marchetti, OMAP, Romai, Parlec, Sauter, Wendel, Wagner, WTO & Zettle Mimatic Driven Tools

And Angle Heads from Alberti, Big Daishowa, Madaula, OMG, Su-Matic, MPA, Bristol Tool, Benz, Gerrardi, Zettle Mimatic, Pibomulti, Heimatec

We are also the Official UK Service Centre for Eppinger Tooling and approved to repair all major brands of Driven Tooling.

Please do not try to repair your own Tools as most wear is difficult to detect without thorough cleaning and re-assembling. A tool without the correct gear backlash and bearing pre-load will cause your Tool to prematurely fail and create further damage to the bearing, seal diameters and gears. We only use the correct high precision bearings and seals as well as the industry standard lubrication and adhesives.

We keep your machine tooling downtime to the minimum by offering you the fastest possible turnaround.

Keep you Tooling maintained regularly to ensure they operate in their best optimum condition and to give increased longevity.

We look forward to answering any questions you may have and to start maintaining your Tooling.

See our contact details at the top of the page.